Groups

shale pits

About the group shale pits and bings of britian

Created 26 June 2012

cell |

||

|

tommy |

|

Many consider that the world's first commercial scale oil refinery was at Inchcross near Bathgate in central Scotland. Here from 1851, James "paraffin" Young and his partners produced a range of mineral oils from the local coals, several years before the first oilwell was drilled in the USA. James Young adapted gas-making technology and patented a process in which cannel coal was heated to a specified temperature within an enclosed vessel or "retort" in order to release an oil vapour. During the 1850's Young and his partners prospered on their virtual monopoly of the mineral oil trade and successfully defended their patents in a number of court cases. Licences were granted to use Young's process in many parts of the world. For a short period, cannel coal was even exported from Scotland to be processed in oilworks on the east coast of the USA. Young's patent expired in 1862, by which time supplies of cannel coal at Bathgate were close to exhaustion and cheap American petroleum was flooding onto the international market. Many tried to emulate Young's success during the "oilmania" of 1863-4 by opening small oilworks throughout the Scottish coalfields using local cannel coals or other "coal shales". Most were doomed to failure although coal oil continued to be produced into the 1880's, notably in the Airdrie and Paisley areas Young realised that the future of the Scottish oil industry lay with the use of oilshale rather than coal. This unusual black mineral, very different from coal, was found beneath much of West Lothian and parts of Midlothian and Fife. It was first used to produce oil at works in the Broxburn area in about 1860. Young established "Young's Paraffin Light and Mineral Oil Company" to develop and operate a massive new integrated oilworks, refinery and candleworks at Addiewell. This was one of the largest industrial undertakings in Scotland at that time and was linked to a number of shale mines in the West Calder area and served by the new village of Addiewell. Young retired from the operation of the company in 1870. Many new shale oil companies were established to challenge the dominance of Young's Oil Company. New patents for the design of more efficient retorts aided the success of the Broxburn Oil Company (established 1878) and the Pumpherston Oil Company (established 1892). There were also notable failures such as the Burntisland Oil Company (1881-1905) and the Linlithgow Oil Company (1884-1904) in which large investments were lost in ill conceived ventures. The first decade of the 20th century was a period of great prosperity for the six surviving Scottish shale oil companies. A growing market for oil, and for the ammonium sulphate fertiliser produced as a lucrative by-product of the retorting process, allowed the companies to invest in new oil works using the latest electrical equipment and in the construction of good quality workers housing. At the height of the industry in about 1912, over 12,000 were employed and output accounted for about 2% of the world's oil production. Scottish technical expertise played an important role in the development of oil industries throughout the world. The fortunes of the Scottish shale oil industry changed rapidly during the first world war. A government-supported scheme to develop British oil interests in the Persian Gulf quickly led to the import of cheap crude oil which undermined the viability of the Scottish industry. Government action first created a joint marketing organisation for the Scottish shale oil companies and then oversaw their amalgamation within Scottish Oils Ltd, part of the government backed Anglo-Persian Oil Company. In 1919 a pipeline was laid to carry imported crude oil from Grangemouth docks to Uphall shale oil works, which was used as a testbed for refining imported oils. This experience was then applied to the design of Grangemouth refinery, opened in 1924. The shale oil industry suffered in the economic uncertainty and labour unrest that followed the war, and eventually management and workforce agreed to an independent enquiry into its future. This found no economic basis for continuation of the shale oil industry and soon led to the closure of many oilworks and mines causing great hardship, particularly in more remote communities. To avoid the disastrous social consequences of complete closure of the industry, a preferential rate of tax on home produced road fuels was introduced in 1929. New cracking plant was constructed at Pumpherston refinery to convert most of the industry's output to diesel and petrol. There was much new investment to boost shale oil production immediately before the second world war as it was feared that imported oil supplies would be threatened in case of conflict. New mines were sunk and others modernised and a massive new modern crude oil works was opened at Westwood near West Calder in 1941. Following the war most of the older oilworks were gradually closed. Westwood continued to produce crude oil for refining at Pumpherston until the final closure of the industry in 1962. In about 1946, experiments at Pumpherston led to the production from shale oil of some of the first synthetic detergents. Production was rapidly developed, lately using imported oils. The Pumpherston detergent plant continued until 1993; the last tangible link with the shale oil industry in Scotland. |

kev |

|

True oilshale is found in the area of Scotland roughly defined by drawing a line on the map joining Tarbrax, Blackness, Anstruther, and Straiton. Many of the rocks within this area were formed during the lower Carboniferous (Dinantian) period, about 340 million years ago. To the west, north and east of the area lie the slightly more recent upper Carboniferous rocks that include most of Scotland's coalfields. (See the coal oil section for details of coal minerals once used for oil production). The area of this shalefield is thought by geologists to represent the site of Lake Cadell, a shallow area of static water on the edge of a giant continent that existed then disappeared on several occasions over a period of several tens of million of years. The rocks of the shale field represent a complex succession of sandstones, limestones, shales, oilshales and a few seams of coal, indicating that the area lay at various times beneath saltwater, freshwater and a low-lying swamp. Whilst such series of sedimentary rocks are common elsewhere, there are few places in the world where rocks similar to Scottish oilshale occur. It is thought that very unusual conditions must have existed in Lake Cadell that encouraged prolonged blooms of algae, the remains of which have been gradually transformed into the black, carbonaceous matter found in oilshale. At least eleven distinct seams of oilshale are found throughout the shalefield, indicating that the black lagoon of Lake Cadell must have existed on many occasions during the course of about 20 million years. Some seams, such as the Fells Shale, seldom exceed a metre in width, indicating that appropriate conditions in Lake Cadell existed for a fairly sort geological period. Other seams are much wider; the Pumpherston shales, for instance, consist of five parallel seams, interspersed with other rocks, totalling up to 15m in width, suggesting a more prolonged and complex geology. Seams of oil shale vary in the amount of oil they yield; the richest shale produced as much as 40 gallons of oil per ton of shale, although shales yielding as little as 15 were exploited in the later days of the industry. While most oilshale was "plain", composed of microscopically thin parallel layers; areas of "curly" shale were often encountered in which the fine layers had been contorted while still soft layers of silt. Over the course of geological time, the strata of oilshale and accompanying sedimentary rocks have been fractured, bent and tilted through the action of faults and other earth movements. Volcanic action has forced its way through sedimentary strata and injected molten rocks into cracks between layers. Such heat often drove off oil to leave a shale of no commercial value. Working the Oilshale This complex geology made shale mining a highly unpredictable business. Faulting of the rocks usually restricted the extent of shale accessible from any one shaft, and seams of shale were often steeply inclined, adding to the difficulty in their working. It was never known when the quality of a seam of oilshale might suddenly deteriorate, or where burnt shale or "wants" (areas where the shale seam was completely missing) might be encountered. Seams of shale were worked by mines; inclined adits which usually followed seams of shale into the ground from their outcrop at the surface, and by pits; vertical shafts sunk to meet underground seams. Some quarrying or opencast working took place in the earliest days of the industry and resumed in the 1940's following the introduction of draglines and other earthmoving machinery. Underground, seams of shale were usually worked by the stoop and room method in which the shale was mined to form a rectangular network of tunnels (or rooms) leaving the stoops (pillars of unworked shale) to support the roof. Once the network of rooms had been extended to all accessible areas of shale, the stoops were gradually removed, starting in the areas most distant to the mine entrance, and the roof allowed to collapse. Longwall working was used in certain areas of the shalefield, in which shale was worked along a long front and waste stone was used to build walls that supported the mine roof around access roads. Longwall working became more usual following introduction of shale-cutting machinery in the 1930's. Both methods of working could cause subsidence at the surface, but usually care was taken to avoid undermining buildings and services. Understanding Mine Plans Since 1872, there has been a legal requirement to deposit all mine abandonment plans with the relevant authority. These plans are now held by the British Geological Survey, while a range of other shale mine plans also survive in the Almond Valley collection. Despite these records, it is often difficult to identify particular mines or pits and the areas of shale worked from them. Not all of the many shafts and adits marked on mine plans and OS maps yielded much shale; many were exploratory workings that never warranted further development, others were "air pits" providing ventilation, or alternative route of access to underground workings. Many mine plans also show the location of boreholes sunk in advance to workings to determine the extent and quality of shale seams. It remains difficult to identify all productive shale pits and mines. Some were known by several names, some were known only by a number, some changed identity when ownership changed or when a new shaft or adit was sunk. Young's Oil Co. were exceptional in consecutively numbering their mines and pits, with a sequence extending into the 40's. Often this number was prefaced by a geographical location. Other companies were much less systematic in naming their shale workings and it is often difficult, for instance, to differentiate between the many different "No. 2 pits". Since 1862, it has been a legal requirement to provide more than one access into underground workings. It became usual to sink two adjacent shafts or two parallel adits. Men and fresh air would enter the mine by the downcast shaft, whilst shale and stale air would be drawn up the upcast shaft. There were however many variations to this arrangement. As workings were linked underground, there might be a number of mines or pits providing access into an area of workings. In some instances a "stone mine" might be driven through barren ground to access further areas of productive shale. Many mines or shafts provided access to more than one seam of oil shale; some mine plans illustrate a single seam on each sheet, but more usually different seams, which might overlap, were colour coded on a single plan. In areas with complex geology and a long history of working, particularly complicated situations occurred. It is possible to stand at certain locations in West Lothian where three different seams of shale have been mined beneath your feet, each linked to a different mine or pit. |

kev |

|

This section aims to identify and describe all housing constructed or owned by Scottish shale oil companies. It has not yet been extended to coal-oil areas, where coal mining was an established industry and housing was seldom constructed exclusively for oil workers. Most reserves of oil shale lay beneath rural areas where there were few existing towns to accommodate an influx of incoming workers. Oil companies therefore needed to construct housing for their workforce, often in the shadow of their oil works and mines. Remote from established settlements, these shale villages developed as tight-knit communities with their own special character. Settlements of temporary wooden huts were sometimes built to house navvies employed in the construction of oil works and mines. At some sites, such as Addiewell and Oakbank, these remained in use for several years. Permanent housing was inevitable built in "rows", as was the tradition in mining and farming districts throughout Scotland. A row, usually built of brick with a slated roof, would be subdivided into anything from four and twelve homes. Early housing was often quickly and cheaply constructed with many homes consisting of a single room. Sometimes single or double apartment houses were built back-to-back within a row. As the industry developed, two-roomed "through houses" became more usual, with a front parlour and a back kitchen cum bedroom, and doors front and back. At various locations, including Addiewell, Broxburn, Tarbrax and Oakbank, two-roomed houses were constructed in two-storey blocks; the upper house being reached by outside stairs. In early housing, many residents shared in a dry closet and ash-pit set between the rows, while water was drawn from a common "well" or stand pipe. From about 1900 most new houses were equipped with a sink and flushing toilet fitted within sculleries projecting from the back of each dwelling. Many existing houses were modernised at that time by adding sculleries equipped with the latest amenities. Wash houses were also constructed between the rows, often shared between a number of neighbours. Housing built to serve new or re-constructed oil works during the prosperous early years of the 20th century continued to be built in rows, but were greatly more spacious and of better quality than previously. Many had gardens, drying greens and attic bedrooms. Following the creation of Scottish Oils Ltd in 1919, some generously dimensioned homes were built at Uphall and Philpstoun, inspired by the Garden City movement. In many villages, housing was allocated according to rank within the company; spacious rows were provided for foremen, and semi-detached villas for managers. Much of the early housing, notably in the West Calder area, was poorly constructed and soon deteriorated into insanitary slums. Many of these were demolished during the 1920s and 30's, and their occupants re-homed in new County Council estates. As the industry continued to contract following World War Two, other housing became redundant and was demolished, often leaving green fields where villages once existed. Scottish Oils Ltd sold off most of their remaining housing stock during the 1960's. Modernised, these continue to provide sound and comfortable homes with a special history. Greendykes Road, Broxburn c.1910, showing examples of different styles of oil company housing. Bells Rows? Two apartment single storey homes built c.1868. These homes were subsequently fitted with sculleries projecting onto the pavement, and survived until c.1960. Greendykes Road Rows. Two apartment, two storey homes built c.1878. When photographed, these homes had already been modernised by fitting a scullery to downstairs houses, with similar facilities at the stairhead (on the opposite side of the block) for upstairs houses. Demolished c.1960. Albyn Cottages (seen in the distance), a row of superior two apartment homes built c.1878 which are still extant. Poynter's Row. A row of twelve simple single room dwellings built c.1864 and demolished c.1932. |

kev |

|

Snippets At Broxburn a new crude work has been erected, and a new shale mine sunk at a part of the neighbourhood known as "The Roman Camp." This is intended to take in the Pumpherston shales, and is on the Drumshoreland section of the company's mineral field. The new works are expected to start early next year. Otherwise, and the notwithstanding the depression, matters have been proceeding smoothly. The Glasgow Herald, 29nd December 1892. Accident Records 27th December 1914, death of William French after a fall from an engine in the engine house 15th October 1918, death of Patrick Smith after being knocked down by a runaway hutch 20th May 1920, death of Walter Waddell Wilson after being run over by a railway waggon 8th June 1923, death of Robert Tweedie Davie as a result of being struck by a locomotive engine |

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

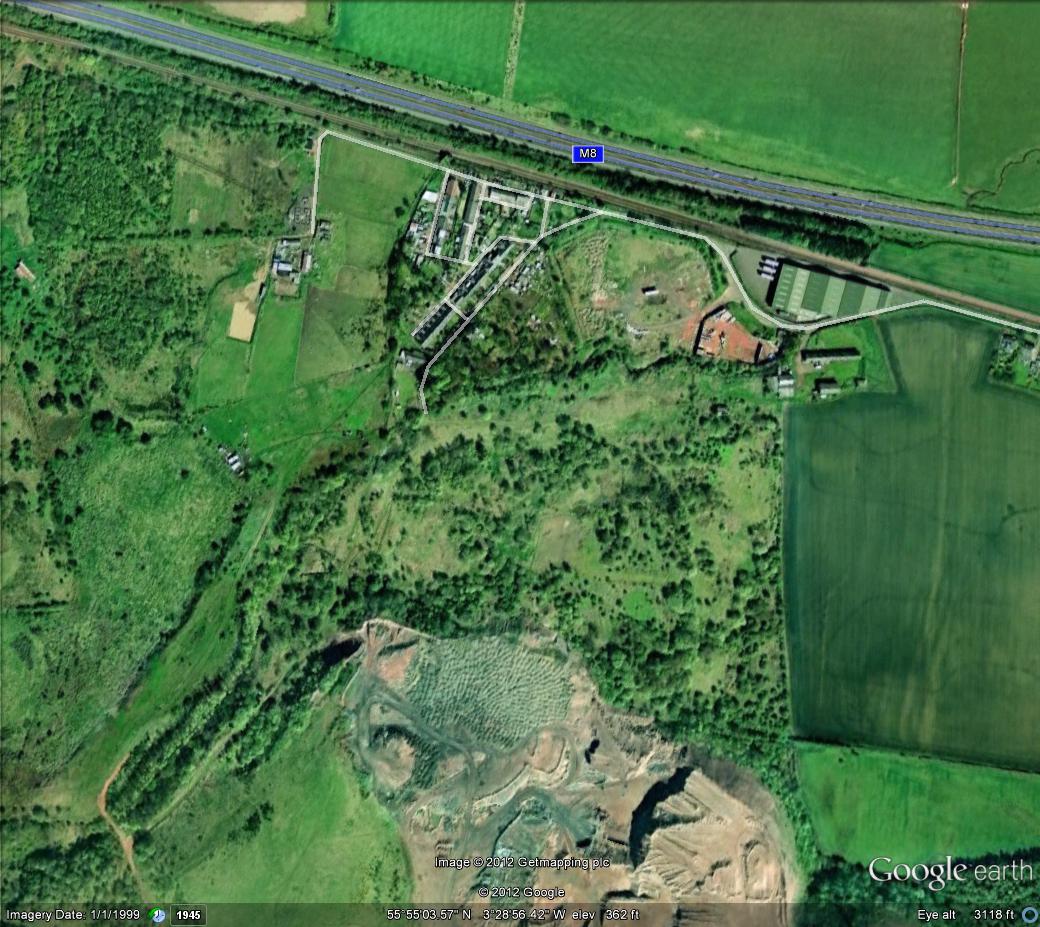

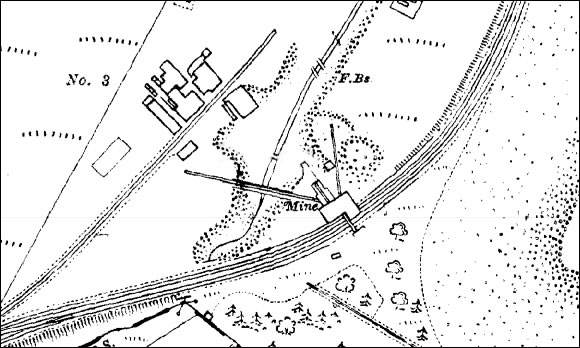

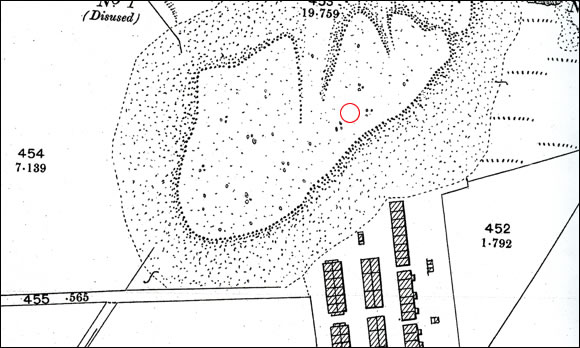

Location 55.914166, -3.486065, Shale-field Pumpherston shale field Dates opened and closed Closed 1918 Owner Broxburn Oil Company Type of working Inclined adit Seams worked Jubilee, Curly, Maybrick and Plain seams of the Pumpherston shale Oil works served Roman Camps Oil Works Current status of site Waste land Background One of a sequence of steeply inclined mines following the outcrop of Pumpherston shales along the western arm of the Pumpherston anticline. The O.S. map appears to show an adit emerging from the western bank of the Caw Burn, crossing the steep valley on a tressle bridge to reach an elevated staging and screens from where shale could be discharged into standard gauge railway wagons. The range of buildings labelled "No.3" seem likely to be associated with a shaft serving a parallel underground incline. Substantial re-grading of the area has taken place since closure of the mine and little remains to mark the workings other that retaining walls built beside the Caw Burn. |

kev |

|

Location 55.934527, -3521900, Shale-field Broxburn District Dates opened and closed Abandoned 1886 and 1909 Owner Uphall Oil Co. ?, Young's Paraffin Light and Mineral Oil Co. Type of working Vertical shaft Seams worked Broxburn shale Oil works served Uphall Oil Works Current status of site Rough grazing Background An early pit, closed in 1886, but subsequently linked to the workings of Forkneuk No. 9 & 10, to the south, and Forkneuk No.38 to the north. Linked by standard gauge railway to Uphall Oil Works. The pit site lies within a grazed area pock-marked with subsidence. No trace remains of any pithead buildings. |

kev |

|

|

kev |

|

|

kev |

|

Location 55.935006, -3.511978 Shale-field Broxburn district Dates opened and closed Open pre-1896, closed 1910 Owner Broxburn Oil Company Type of working Inclined adit Seams worked Broxburn, Grey, Upper Grey and Curly shales Oil works served Broxburn Current status of site Waste land and agriculture, with bing intact but no surviving remains of buildings Background One of three Crossgreen mines serving Broxburn Oil Works. No.1 seem to have had two adits, one heading to the south, the other south east. The workings seem to caused considerable subsidence. |

kev |

|

|

kev |

|

Location 55.935526, -3.502378, Shale-field Broxburn district Dates opened and closed Opened 1917, closed 1919 Owner Broxburn Oil Company Type of working Inclined adit at a gradient of 1 in 3.5 Seams worked Raeburn shale Oil works served Broxburn Oil Works Current status of site Re-developed for housing in Carledubs Avenue Background A very short-lived mine "troubled by wants" - the disappearance of a seam of productive shale. Linked to Broxburn Oil Works by standard gauge mineral railway. |

kev |

|

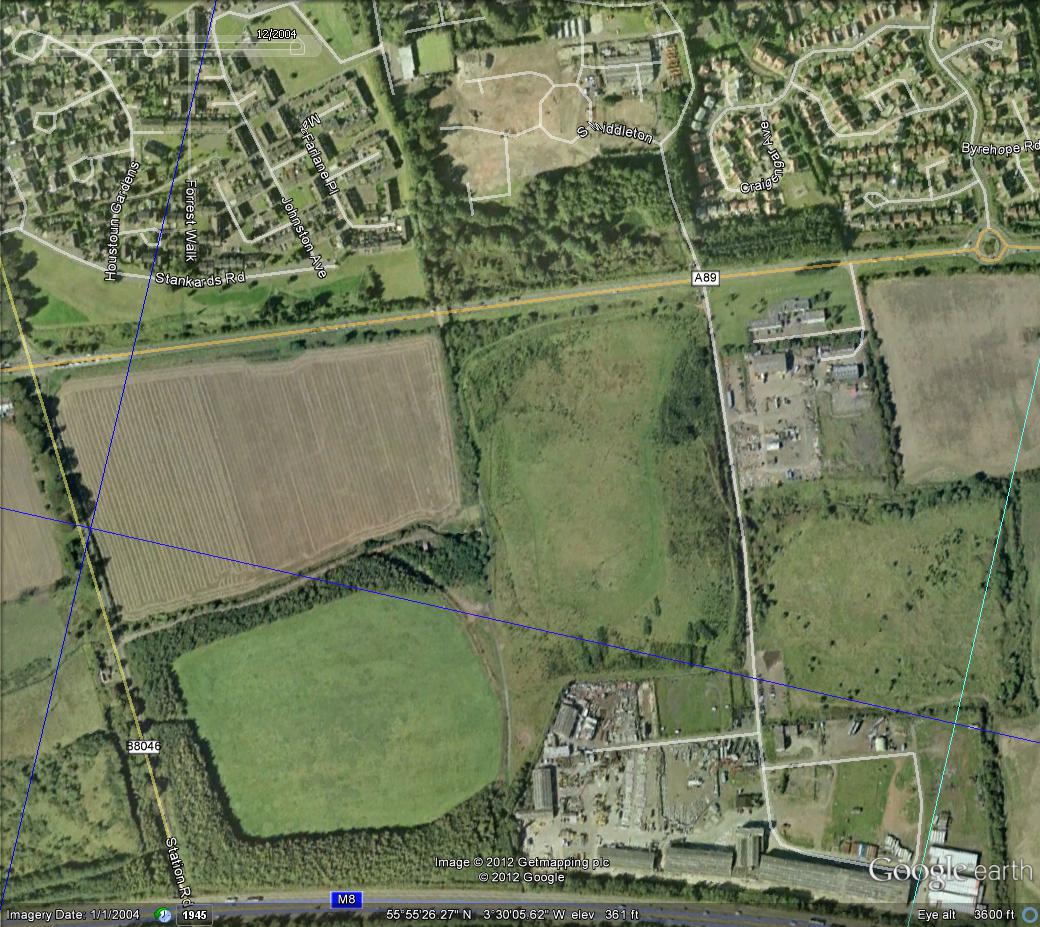

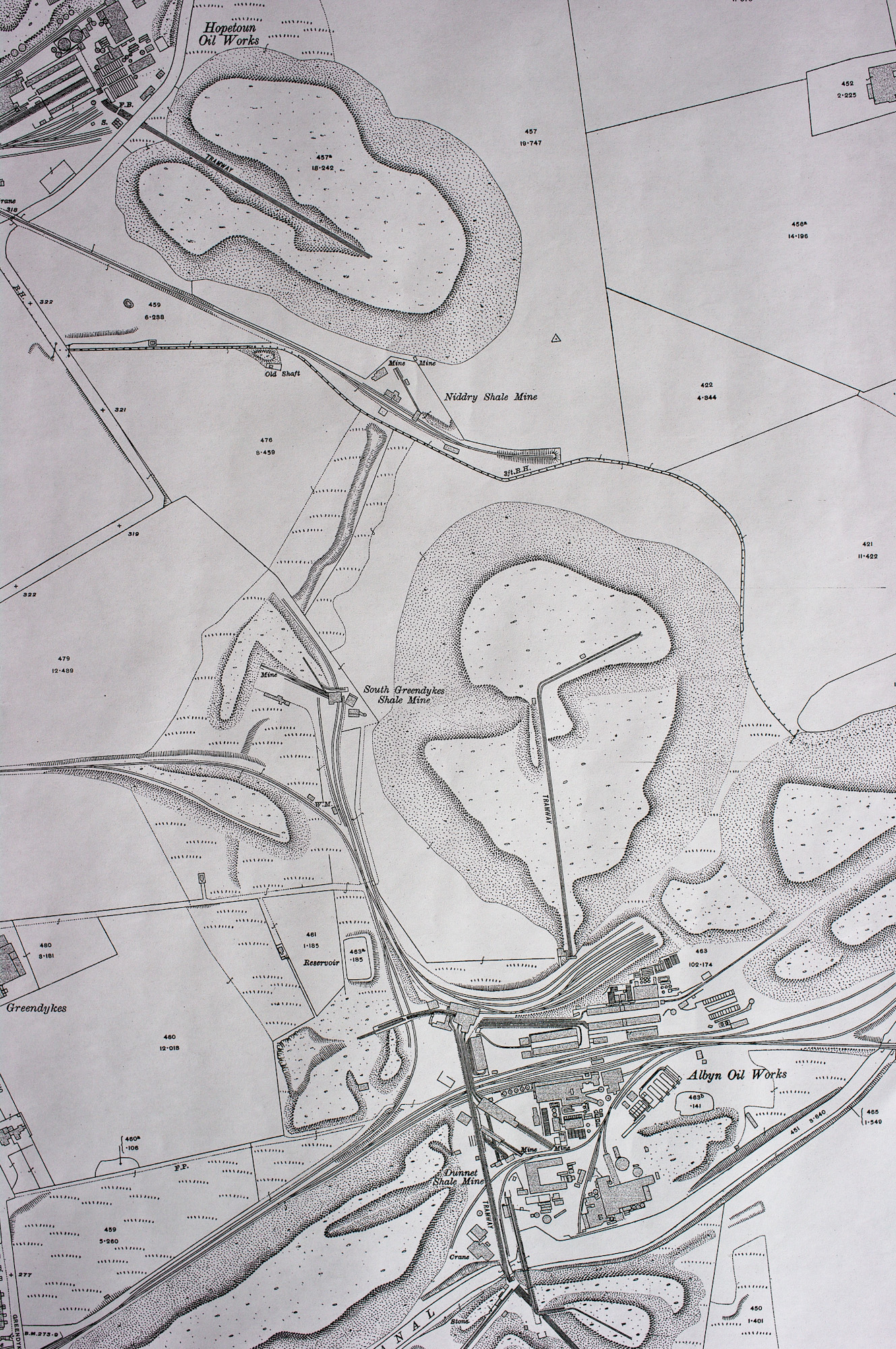

Location 55.941890, -3.461422, Alternative names Albyn shale mine Dates opened and closed Broxburn shale workings abandoned 1893-4, Curly shale working abandoned 1905 Owner Broxburn Oil Company Ltd Type of working Inclined adit Seams worked Broxburn and Curly- shales Oil works served Broxburn (Albyn) Oil Works Current status of site Industrial site and derelict ground Background A substantial mine driven from a site in the heart of Broxburn Oil Works. The main roadway headed to the south east following the dip of the Broxburn shale. |

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

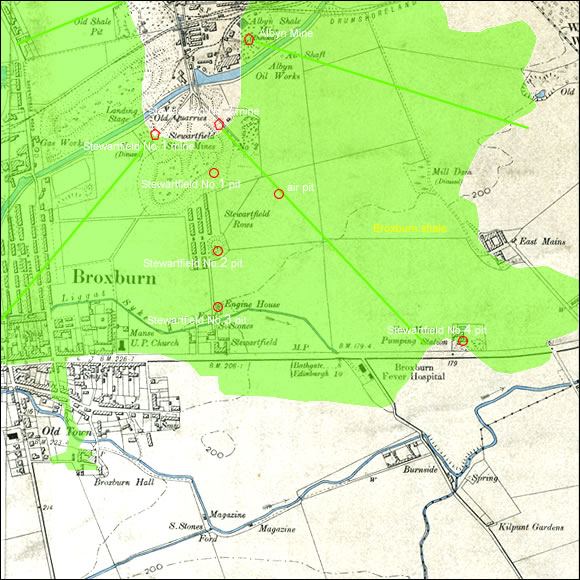

Stewartfield No.1 mine exploited Broxburn shale reserves lying to the south west of Broxburn Oil Works by means of a long roadway through earlier shale workings. Hutches of shale would emerge from the adit into an area of opencasting and hauled onto staging (also serving No.2 mine) before crossing the canal to Broxburn Oil Works. |

kev |

|

|

kev |

|

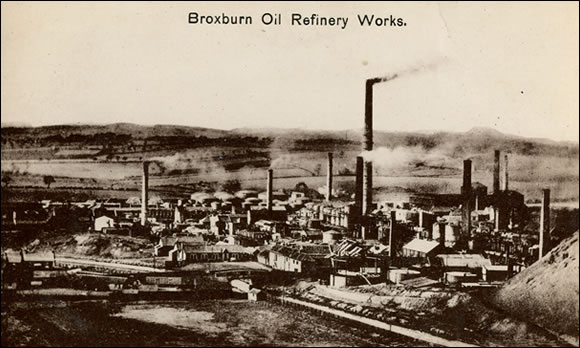

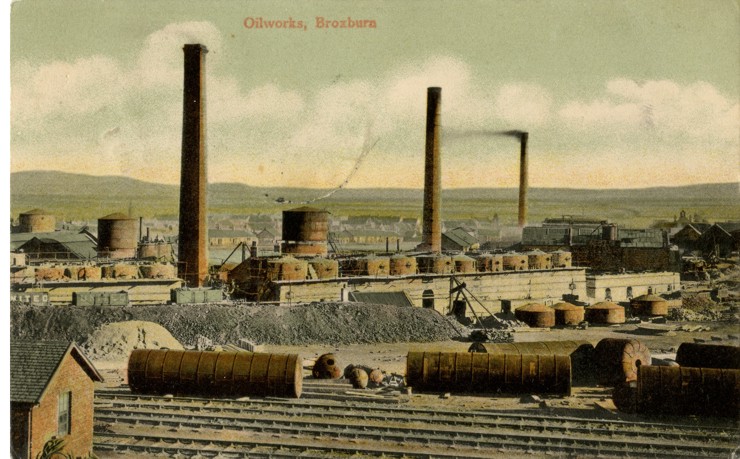

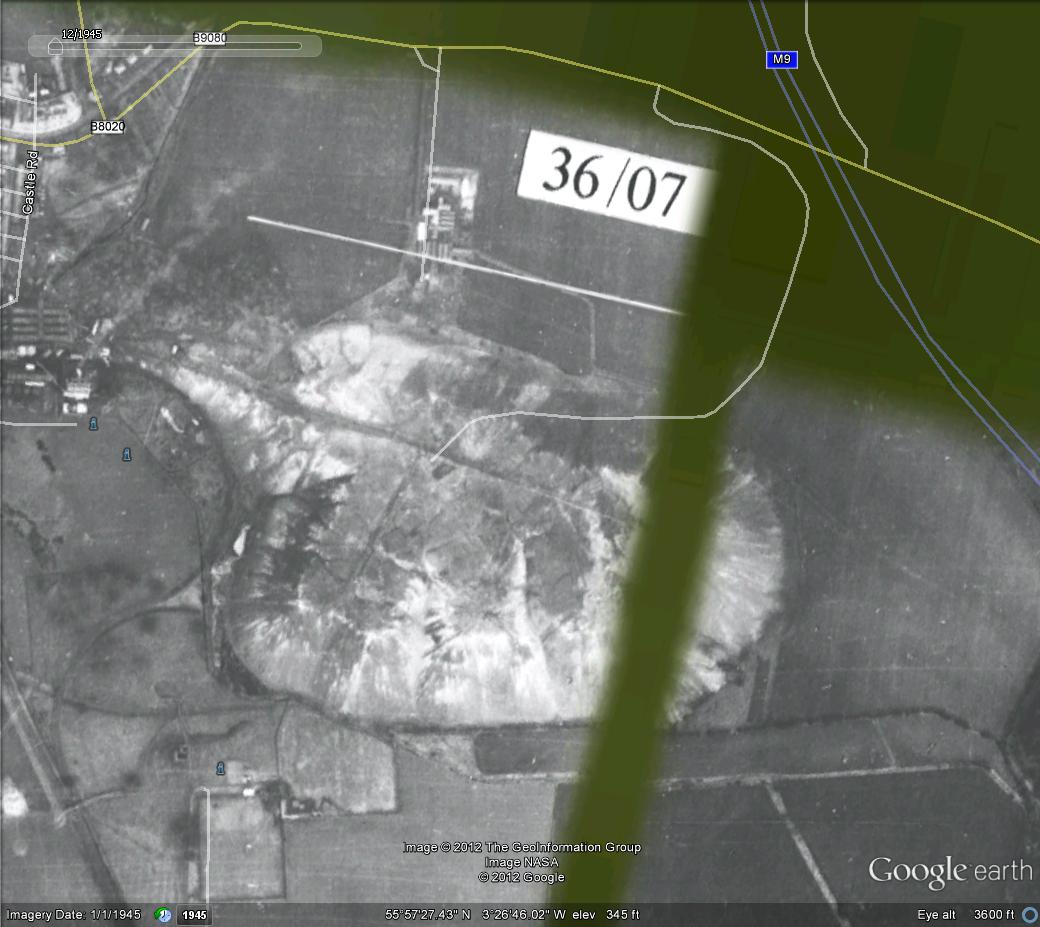

Link to "An Introduction to Broxburn's early oil works." Location Refinery: 55.938243, -3.474418, Retorts: 55.942615, -3.462655 Former parish and county Parish of Uphall, Linlithgowshire Current local authority area West Lothian Construction history Constructed from 1878 incorporating sites of earlier oilworks Ownership history Broxburn Oil Company Ltd Demolition history Crude oilworks demolished c.1937, refinery demolished.c.1957, site cleared c.1962 Current status of site Industrial units and waste ground. Part of the candleworks building still extant Background Redwood noted: "In 1877 the famous Broxburn Oil Company, Limited was floated, with a capital of £180,000. This company bought up the oil work and shale fields acquired by Bell in 1862. Bell, besides being a large stock-holder, also took and active interest in the management of the company, which latter has been one of the greater successes in the history of the Scotch oil industry." The first oil works to challenge the scale of James Young's Addiewell plant, Broxburn was an integrated industrial complex equipped to undertake all processes necessary to transform shale into a full range of oil and wax products, including the manufacture of candles. From the outset the works were equipped with Henderson patent retorts which provided a major competitive advantage and allowed the company to dominate the industry for the next decade. |

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

kev |

|

|

a recent view of one of the shale bings

|

kev |

In 1919 the shale oil industry was consolidated under Scottish Oils Ltd which was a subsidiary of Anglo Persian Oil Company (later BP). The Pumpherston Works became the central refinery for all Scottish shale oil production. By 1938 there was 12 mines, 5 works and the Pumpherston refinery, they also had their own workshops at Middleton Hall

Uphall, Pumpherston Refinery, NT 0745 6950

Opened before 1884 by the Pumpherston Oil Co, refining of crude shale oil ceased in1962, although some crude oil from Nottinghamshire continued to be refined there until 1964. Detergent production continued until c1995.

In 1884 electric lighting was applied to a section of the Pumpherston works, but faulty insulation caused the destruction by fire of the department concerned. Full electrification took place after Niddry Castle.

1950s electricity production description from Scottish Oils Ltd. “Originally two 400kw alternators each direct coupled to three crank vertical triple expansion high speed steam engines. Both of these were replaced three steam turbo alternators. Latterly a 1.5MW and two 1MW turbo alternators with a total boiler capacity of 168000lb/hr”

Uphall, Roman Camp, NT 0735 7037

Just north of the Pumpherston refinery, the Broxburn Oil Company constructed new mines, oilworks including a bank of Henderson patent retorts and company village at Roman Camps in 1892. It continued in production until c.1955 and was mostly cleared by c1958. The manager's house was still in existence in 1998

1950s electricity production description from Scottish Oils Ltd. “4 generating sets with a total capacity of 1.45MW, boiler capacity is 93000lbs/hr”

Winchburgh, Niddry Castle, NT 0930 7476

The Niddry Castle Oilworks were constructed by the Oakbank Oil Company in c1902 and introduced many technical innovations such as the widespread use of electrical power. Crude oil produced there was transported to Oakbank for refining. The oilworks closed in 1960, the last but one Scottish shale oil works to remain in operation.

1950s description from Scottish Oils Ltd. “When the works were built in 1902 they were the first to completely adopt electricity for works and mines. Originally there were two vertical compound high speed engines of the trunk piston type, direct coupled to 200kw 3300v 3 phase 25hrz with belt driven exciters. These were replaced by four Beliss, three cranked compound high speed generating sets. Two of the Beliss sets were replaced by two 1.8MW turbo alternators working at 3300V 3 phase 50hrz. A frequency changer of 850kw has been installed and operates in conjunction with the two remaining 500kw sets to supply 25hrz mining load to the eastern area.

During extension to the works the opportunity was taken to change the existing plant to 50hrz.

Shale is conveyed from the mines to Niddry Castle works via a 1.5 mile electric railway with 6 electric trolley locos operating at 500/550V DC, this dates back to 1902.. The current boiler capacity is three 30000lb/hr and two 15000lb/hr boilers.” This works also fed Glendevon mine with DC current via a 300kw glass bulb rectifier. The electric railway survived until closure of the works in 1960 and No.2, one of the original American-built engines was preserved by the National Museums of Scotland.

West Calder, Addiewell Works, NT 0001 6256 (bing)

Opened by Young's Paraffin Light and Mineral Oil Company Limited in 1868 and was one of the largest in the area, closed after 1950.

1950s description from Scottish Oils Ltd, Two 1MW turbo alternators 4 18000lbs/hr boilers, it also supplied the Baads coalmine at West Calder with DC current via a 400kw glass bulb rectifier.

West Calder, Westwood, NT 009 641 (bing)

Built just before WW2, north west of West Calder, and the site of the five sisters bing, closed after 1950.

1950s description from Scottish Oils Ltd. “Two 1.8MW turbo alternators four 30000lbs/hr boilers, two 500kw Belliss sets are available as standby at Westwood pit”

West Calder, New Tarbrax, NT 0256 5558

South of West Calder, Tarbrax oilworks were constructed in 1904-5 on the site of a previous concern and closed in 1925. The works and their associated mines were notable for their early use of electrical power for winding, haulage and ventilation in mines and general use in the oilworks. The 1st electrical winder in Scotland and known to have operated three steam driven Siemens generators at one time.

Livingston, Dean Oil Works, NT 0305 6843 (bing)

Dean oil works was built on the site of a failed oilworks by The Pumpherston Oil Company in 1897, and supplied crude oil for refining at Pumpherston. The works closed in 1946.

Electrical power for the oilworks and adjacent company village was produced by a steam driven generating plant. The three Siemens alternators were each coupled to 720 bhp Howden triple crank compound steam engines. Each had an output of 500 kW, 3300V, 50 cycles, 3 phase. Exhaust steam from the power plant was used in retorting the shale.

Mid Calder, Oakbank, NT 0781 6600

Oakbank Oil works was constructed c1869 by the Oakbank Oil company on the site of an earlier enterprise founded c1863. Crude oil production ceased in 1925 although the refinery continued to 1935.

The first application of electricity to the Scottish oil industry was in 1879 when in Jan & Dec two licences were held by the British Electric Light Co Ltd for the use of two " Gramme" generators for lighting Oakbank works. Full electrification took place after Niddry Castle.

West Lothian, Philpstoun Works, NT 0500 7703

James Ross & Co. opened a crude oil works at Philipstoun in 1886. The oils produced there was sold for refining elsewhere, although the tars produced may have been processed at the company's tar works in Falkirk. The oilworks were closed in 1935.

In the early days the largest DC plant, a single 600kw Westinghouse turbo generator and three 185kw high speed engine driven generators all working at 550V